Shop by Category

Norton Saint-Gobain

An Industry Leader in Abrasives for 130 Years and Counting

.png)

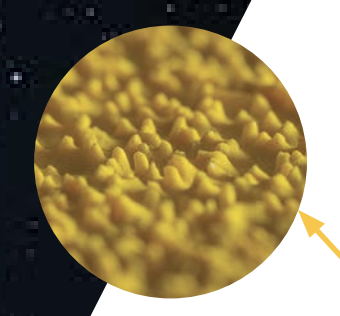

The engineered shaped grain in Norton RazorStar discs features a consistent shape from grain

to grain along with razor-sharp cutting points. The unique patented geometry and tough

micro-structure enable the grain to stay sharp, as new cutting points are exposed when the

grain fractures.

DOWNLOAD THE BROCHURES

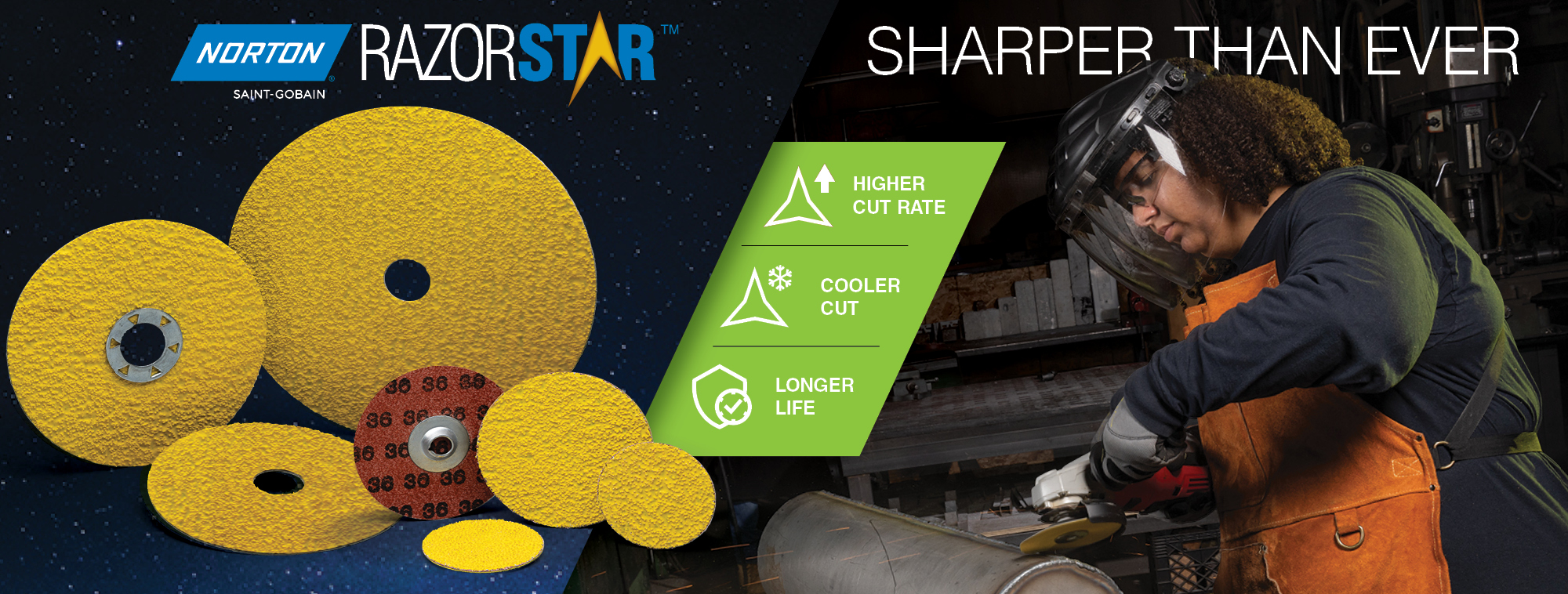

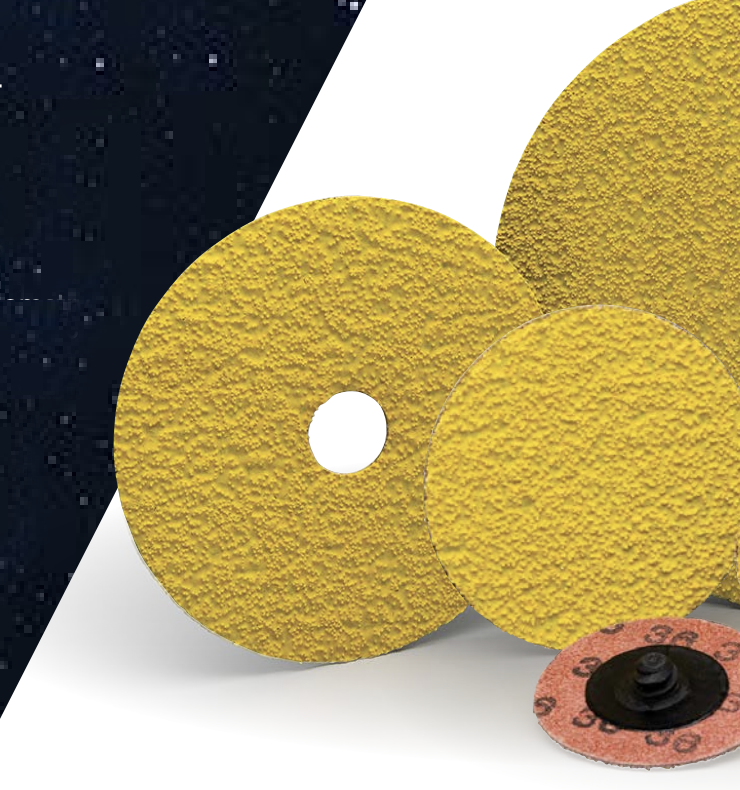

RAZOR STAR DISC

Designed for medium to

high-pressure metal removal in the toughest grinding applications, Norton

RazorStar discs feature 100% ceramic engineered shaped grain which cuts

through metal with unbeatable performance.

RAZOR STAR BELTS

Norton RazorStar belts are designed from top to bottom to

be the most advanced abrasive product, utilizing proprietary shaped grain, a breakthrough technology from one

of the world’s foremost grinding innovators.

PRODUCTS

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Norton RazorStar utilize an engineered ceramic shaped grain. The grain’s unique shape allows for a sharp initial cut while fracturing in a precise manner during use to create new sharp cutting points for higher and faster stock removal rates. The grains stay sharp for longer, reducing dulling, and allowing for cooler cutting, longer belt life and fewer belt change overs.

HIGHER CUT RATE Engineered shaped grain cuts faster and removes more material.

HIGHER CUT RATE Engineered shaped grain cuts faster and removes more material.LONGER LIFE

Unique patent protected geometry enables the grain to stay sharp, allowing for unparalleled disc-life.

COOLER CUT

Design helps to significantly

reduce heat generation and

maintain cooler grinding

The unique combination of razor-sharp grains with a supersized grinding aid helps to significantly reduce heat generation for cooler cuts and longer life on all materials.

A single disc design has been optimized for superior performance on all materials including carbon steel, aluminum, stainless steel and hard-to-grind metals.